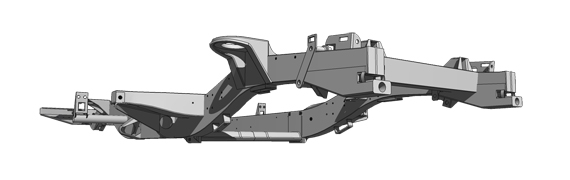

The chassis assembly is the backbone to every Land Rover®.

Unfortunately it’s the one item that get’s the least attention/maintenance and this often results in a rusty, rotten chassis which could be the end for your Land Rover®.

The job of changing the chassis is a complicated procedure but with the AL Services Chassis Swap service you can give your Land Rover® a new lease of life and greatly improve the re-sale value.

The Chassis Replacement Process

AL Services now has a dedicated new workshop in Poole Dorset, equipped with 4 Post Ramp allowing us to re-chassis your Land Rover® quickly and efficiently.

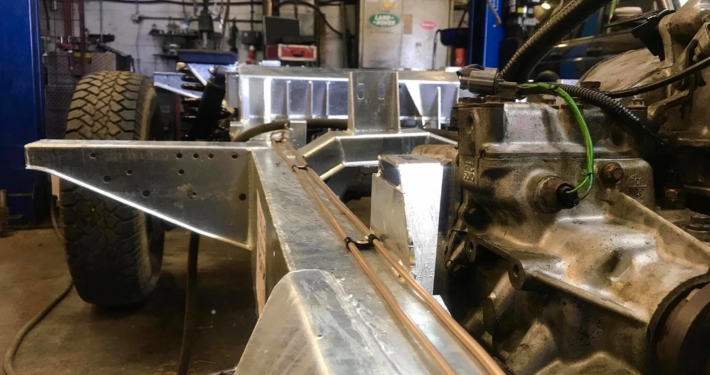

AL Services use Richards Chassis for all our chassis replacements…

Richards Chassis are the number 1 manufacturers of replacement chassis for Land Rover® vehicles in the UK and with over 25 years experience the workmanship and quality of their new galvanised chassis is second to none.

The chassis swap process includes the removal of all body work, drive train and mechanical components from your old worn-out chassis. All components are then re-assembled onto a shiny new, heavy duty galvanised chassis.

As you’d expect, if your old chassis has come to the end of its life, other components such as brake pipes, fuel lines, bolts, clips and bushes may also need replacing. We can discuss your individual requirements and advise you on items we think should be renewed, and because the vehicle is in a bare chassis state these items can be replaced more easily saving you money in the future.